A vacuum pump is an industrial device that is used to remove the air or gas particles from any vessel so as to create a vacuum inside the vessel. It has several industrial uses in the electronics manufacturing industry as well as for extensive scientific research.

It is used in the making of several parts such as CRT tubes, electric bulbs, and lamps, semiconducting materials, glass coating, etc. and for carrying out scientific research in industries like Electron microscopy, radiotherapy, surgery equipment, pharmaceutical processes, and several others.

There are several types of vacuum pumps available that are designed to perfectly suit the various industrial requirements.

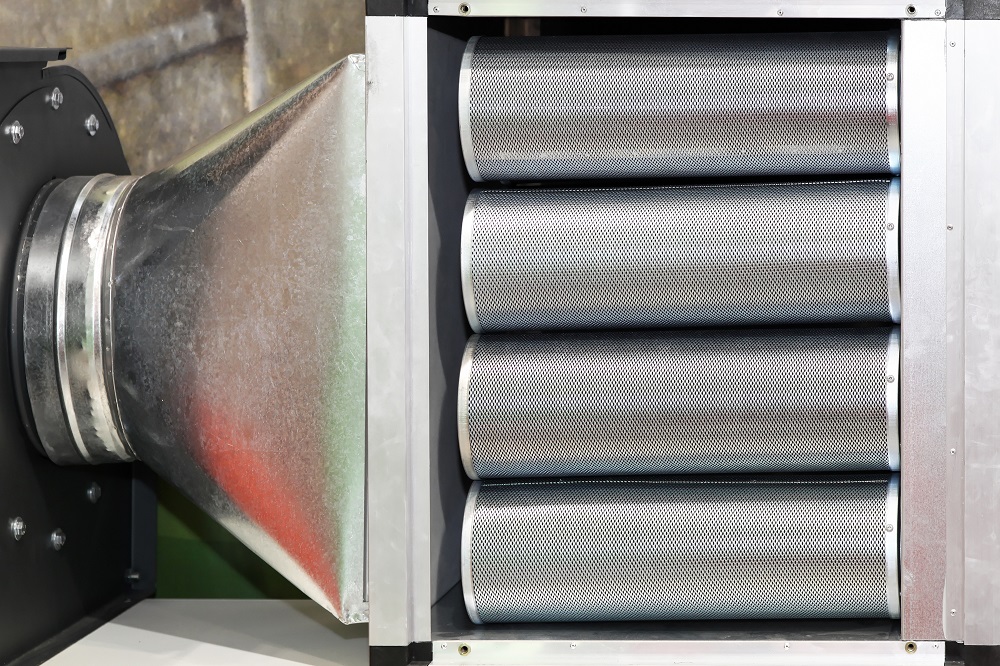

Vacuum filters are additional devices that can be attached to the main machine so that hazardous chemicals and gases that are emitted can be contained so that they do not cause any kind of health hazard as well as to keep the machine running in a perfect condition.

For efficient and safe operation of the machine, filters are required both at the inlet as well as the outlet of the vacuum pump.

Table of Contents

Some Of These Filters Include:

Exhaust Filters:

Air contamination can happen because of pump oils and oil contamination. These organic substances are eventually released into the factory air, which can cause a serious health threat for all factory workers.

Without any exhaust vacuum filters, organic components and hydrocarbons from the pump oil will be exhausted into the air. It is recommended that these filters be changed periodically depending on their type and quality.

Oil Mist Eliminator:

When the vacuum pump is first used, it usually emits a considerable amount of oil vapors into the air. These oil vapors not only contain oil but also any other contaminant that was mixed in the oil used.

The work of the oil mist vacuum filter is to trap the oil that is emitted and return it back and to trap the harmful contaminants so that these vapors do not cause as much harm as they would. It is a highly effective filter and it has a very simple mechanism of a paper filter to trap the oil and return it to the pump.

Charcoal Filters:

Charcoal filters are usually used in the exhaust of vacuum pump and they are used for the final removal and trapping of excess oil, aerosols, hydrocarbons, and trace moisture. They help by trapping foreign materials in the system that would include dust and similar particles.

Charcoal vacuum filters can also be used for the efficient removal of other organic matter and vapors too. Doing so helps ensure the purity of the air. This filter is the final defense and it prevents these substances from polluting the air thereby making a healthier environment to work in.

Silencers:

Silencers can also be installed in vacuum pumps to reduce the noise that is made by the machine. The silencer for each brand of the vacuum pump is different.

Many of these vacuum filters are installed in the outlet of the machine so that the contaminated particles that are released by the machine are trapped to a certain extent and the air released is not as harmful.

For the vacuum pumps that are not vented outside the laboratory, it becomes more vital to install such filters otherwise it would be putting all the workers’ health at risk.

A combination of these filters should be used at both the inlet and the outlet of the machine so that when the oil is put in the machine the oil is also checked for harmful substances and the harmful emissions can be controlled at the outlet.